Industrial Potato French Fries Processing Machine Equipment for Sale

- Model:GG-200

- Capacity:200 kg/h

- Processed Material: Fresh potatoes

- Voltage:380V-3/220V-3

Features

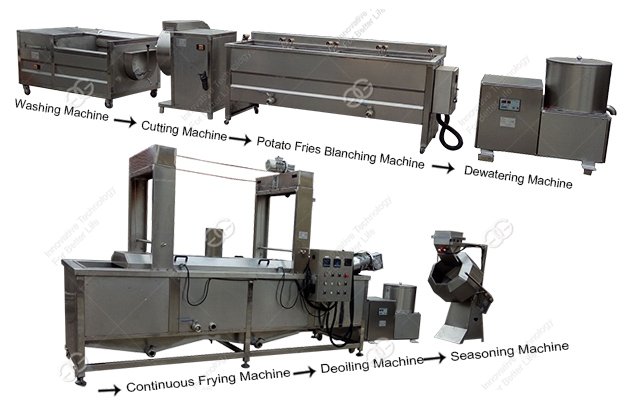

Industrial Potato French Fries Processing Machine Equipment

Industrial Potato French Fries Processing Machine EquipmentThe industrial potato processing machine is used for cleaning and peeling fresh potatoes, processing them into French fries, slice chips, wavy pieces or strips through different knives. After processing, the potato chips or strips are blanched and drained, fried and seasoned to be crispy and delicious. Freshly cut potato chips or potato strips. Potato fries, also named French fries are popular and generally ate as an leisaure food with lunch or dinner, enjoying much popularity. People love this snacks for its unique flavor, crispy taste and golden-brown appearance. Here introduces processing line for producing potato fries.

Advantages of Industrial Potato Processing Equipment

1. Every machine is made of high quality stainless steel, up to health standard, easy to clean.

2. This processing line also can be adjusted to produce potato chips.

3. Low oil consumption, high automatic, high work efficiency, saves labor and energy.

frying french fries

4. Economical and practical, superior quality and competitive price.

5. 100-150 kg/h, 200-300kg/h and 300-500 kg/h, three capacity model for your choice

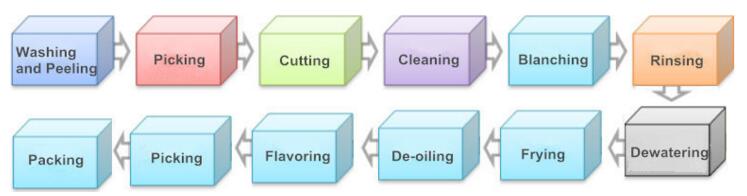

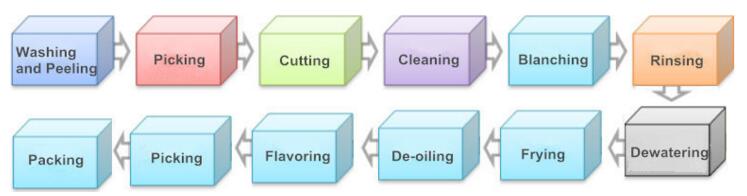

Production Flow for Potato Fries Processing Machine

Production Flow for Potato Fries Processing Machine

Potato washing and peeling----Potato strip cutting----Potato fries blanching---Dewatering---Frying----Deoiling---Flavoring---Frozen

Processing Flow Of Potato French Fries Processing Machine

Hoist - Cleaning Peeler - Picking Line - Cutting Machine - Drifting Machine - Vibration Drain - Air Drying - Fryer - Air Cooling Line - Quick Freezer - Packing Machine

1. Hoisting machine: Automatic lifting and feeding, convenient and efficient, saving manpower

2. Cleaning peeling machine: Automatic potato cleaning, high efficiency and energy saving

3. Picking line: Remove the potato pitted potholes, improve quality

4. Potato cutting machine: Efficient cutting, adjustable size.

5. Conveyor: Lift and transport the potato strips to the blanching machine.

6. Bleaching machine: Remove starch from potato strips, inhibit active enzyme activity, protect color.

7. Vibrate drainer: Remove excess scrap and shake to remove excess moisture

8. Air-cooling line to the water: Air-cooled effect to remove the fries surface moisture, transported to the fryer.

9. Frying machine: Frying color, and optimize the taste.

10. Vibratory drainer: Vibration removes excess oil

11. Air cooling line to oil cooling: Blow off the excess oil on the surface, fully cool the fries in order to enter the freezer

12. Quick-freezing machine - frozen French fries convenient packaging storage and transportation, optimize the taste

13. Packing Machine: Packing Weight According to Customer's Requirements, Fully-Packed Frozen French Fries

Technical Data

| Name | Parameters |

| 1. Potato Washer and Peeler |

Power: 1.5kw Voltage: 380V-3/220V-3 Weight: 180KG Size: 1400*850*800mm Capacity: 600KG/H |

|

2. French Fries Cutter |

Power: 1.1kw Voltage:380v-3/220v-3 Weight: 110KG Size: 950*900*1000mm Capacity: 600KG/H |

|

3. Blanching Machine |

Power :48 kw Voltage :380V-3/220V-3 Capacity :200 kg/h Weight :140kg Dimension :2200*700*950mm |

|

4. Dewater Machine |

Power: 1.5kw Volts: 380v-3/220v-3 Weight: 390KG Size:1000*600*850mm Capacity: 300KG/H |

| 5. French Fries Fryer |

Power :48 kw Voltage :380V-3/220V-3 Capacity :200 kg/h Weight :140kg Dimension :2200*700*950mm |

| 6. De-oiling Machine |

Power: 1.5kw Volts: 380v-3/220v-3 Weight: 390KG Size:1000*600*850mm Capacity: 300KG/H |

| 7. Flavoring machine |

Power: 1.1 kw Voltage: 380V-3/220V-3 Capacity: 300 kg/h Weight:190kg Dimension:1100*800*1300mm |

Related Products

: sherry@gelgoog.com

: sherry@gelgoog.com  : 0086-15515573212

: 0086-15515573212