Crispy Fried Onion Rings Processing Machine

- Model:GG-F200

- Capacity:200kg/h

- Processed Material: Onion

- Voltage:380/220v

Features

This industrial onion processing plant includes onion peeling machine, onion root cutting machine, onion rings cutting machine, fried onion machine, and deoiling machine, seasoning machine, packaging machine and other auxiliary equipment

This fried onion rings production line is kind of equipment for snacks food categories, the produced onions rings taste crisp, delicious, especially for the market demand, favored by the majority of customers at the same time.

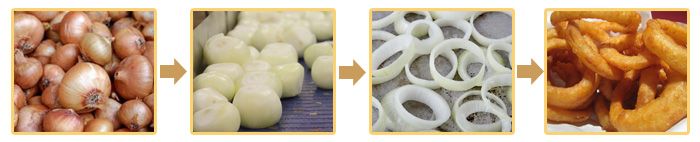

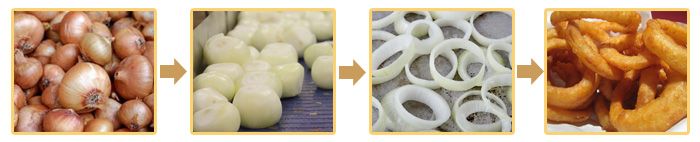

Manufacturing process of Fried Onion Ring Production Line

This fried onion rings production line is kind of equipment for snacks food categories, the produced onions rings taste crisp, delicious, especially for the market demand, favored by the majority of customers at the same time.

Manufacturing process of Fried Onion Ring Production Line

Onion skin peeling -- Onion root cutting -- Slicing-- Washing-- Drying-- Frying -- Deoiling -- Seasoning -- Packing

The pre-treatment process including onion root cutting, peeling and slicing, is specially designed for onion. The other parts can be used for other fried food, such as French fries, banana chips, chicken nuggets, pork rinds, peanut,broad bean and etc..

Following will introduce some machines of this whole onion rings production line:

Following will introduce some machines of this whole onion rings production line:

- Onion Root Cutting Machine and Peeling Machine: This machine can cut onion tops and tails cleanly without damage, suitable for processing different kinds onions for making onion rings, with high efficiency and easy operation. And onion peeler is to remove onion skin.

- Onion Slicing machine: This slicing machine is suitable for slicing onions into fine slices, ideal equipment for making onion ring, and thickness of sliced onion rings can be customized.The slicer machine has wide application, can cut other fruit and vegetable into slices, such as garlic, ginger, potato cucumber, kiwi.

- Bubble Type Washing Machine: This machine is suitable for washing all kinds of fruit and vegetable, here used to wash onion rings, using bubble, cycle surfing, high pressure spray washing to realize thoroughly cleaning.

- Drying Machine: After washing, onions rings need drying for next frying step. This kind of drying machine is ideal equipment for removing surface water. Onion dehydration can be achieved by the high pressure and low temperature airflow, with oil stain and incrustation removing.

- Onion Rings Fryer: Can fry not only onion rings but also other food like broad beans, peanuts, potato chips, spring roll and etc.. Different type machines for your selection, suitable for kinds of food frying. Adopts oil water mixture frying technology.

- Fried Onion Rings Deoiling Machine: After frying, deoiling machine is used to remove extra oil from fried food quickly, and the extra oil will be collected by a plate, so this deolier is economical and practical.

- Flavoring Machine: In order to produce better taste fried onion rings, often add different flavors. Octagonal type seasoning machine, which can mix flavors and onion rings evenly and discharge automatically. Whole machine is made of stainless steel 304.

- Automatic Packing Machine: This automatic packing machine can be used for weighing, filling food, sealing and cutting automatically, suitable for packing any size and shape of puffed food, fried food and baked food. This equipment is controlled by computer, with high automation degree, high efficiency, labor saving.

Fried onion ring processing equipment manufacturers direct sale, good price, there are also more equipment for your choice. Support wholesale and retail, welcome to inquire. Supplier will sincerely serve you. Because of the specialty, so the quality is superior.

Technical Data

| Product Name | Automatic Fried Onion Processing Plant |

| Brand | Gelgoog |

| Final Product | Fried Onion |

| Capacity | 200 kg/h |

| Voltage | 380v, can be customized |

Related Products

: sherry@gelgoog.com

: sherry@gelgoog.com  : 0086-15515573212

: 0086-15515573212